In a previous discussion, we highlighted the Manual Plunge Cooler by MiTeGen and its potential to...

Renaissance of the Manual Plunge Cooler

In our previous exploration of IoT in cryo-EM, we illuminated how technology could democratize the field, making it more accessible to a broader base of users. Now, we focus on the Manual Plunge Freezer, a device that, in conjunction with IoT, serves as another essential piece in this puzzle. The resurgence of such manual devices in labs worldwide represents an effort to bring cryo-EM preparation into the hands of more researchers.

Developed by MiTeGen, the Manual Plunge Cooler is a sturdy, user-friendly device designed for simplified and efficient vitrification of samples for cryo-EM. Let's delve into how it's making cryo-EM more accessible, reducing the barriers for novices, and facilitating collaboration among diverse teams.

Encouraging self-sufficiency through affordability

Often, the cryo-EM field is stuck in a Catch-22 situation where the demand for trained users contrasts sharply with the resources necessary for training. The Manual Plunge Cooler provides an accessible stepping stone towards overcoming this conundrum.

Being substantially less expensive than robotic alternatives, this device lowers the financial entry barrier. Its robust and durable design also ensures a long lifespan, promising enduring use, and cost-effective value for labs. This affordability allows more labs to equip themselves with the necessary tools, enabling a greater number of researchers to independently prepare samples and become self-sufficient in the cryo-EM workflow.

Easing the learning curve

Teaching cryo-EM is a delicate task. The fear of potential damage a novice might inflict on expensive equipment naturally makes trainers cautious, often leading to a selective approach in choosing who they train. This inherently leaves some potential users behind.

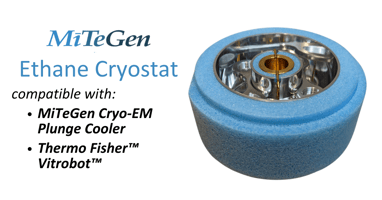

The Manual Plunge Cooler, with its durable design and affordable cost, mitigates some of these fears. The Ethane Cryostat, in particular, aids in the careful handling of liquid ethane. Novices often find ethane liquification challenging, and in the process, the ethane might freeze, potentially damaging tweezers released into it. With the temperature-controlled environment provided by the Ethane Cryostat, such mishaps can be avoided, reducing the number of training iterations needed to handle vitrification confidently. Consequently, the pool of those who can be trained to master the vitrification device is broadened.

Facilitating collaboration through distribution

The Manual Plunge Cooler can significantly enhance collaboration within large organizations like pharmaceutical companies. Its affordability and robustness facilitate its deployment across various locations, fostering a more integrated work environment.

Having a plunge freezer at additional locations, such as satellite structural biology or protein production teams, allows for closer connections with the main cryo-EM campus. It encourages a better understanding of the workflow across different teams, making the knowledge of cryo-EM more widely spread across the organization.

The Renaissance of the Manual Plunge Cooler by MiTeGen signals a valuable step towards the broader democratization of cryo-EM. By easing financial constraints, simplifying the learning process, and promoting distributed collaboration, it feeds into the larger initiative of making cryo-EM widely accessible to the scientific community.

Useful links

1. Learn more about the Manual Plunge Cooler and Temperature Controlled Ethane Cryostat.

2. MiTeGen website.